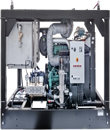

Description

High‑pressure spray head with independent drive for tank cleaning. The working flow and pressure can be individually adapted to the cleaning task concerned so that the spray head is virtually universal in application. The spray head for tank interior cleaning comprises a drive element, a carrier tube and the spray head itself. This form of construction makes the spray head particularly suitable for cleaning the interiors of tanks with small access openings. The spatial rotation of spray head nozzles in two planes is effected through the positively‑coupled drive of the nozzle carrier. The assymetrical gearing with its large number of teeth ensures closely spaced jet passes and thus intensive cleaning of all a tank`s interior surfaces. Rotation is effected by an electric motor so the speed of rotation is independent of the rate of flow of the cleaning medium. All parts coming into contact with the medium are of stainless steel. All bearing surfaces of the shafts are coated. Shafts are sealed by means of teflon profile rings to facilitate universal application with all types of cleaning media over a wide range of pH values. The connecting flange is mounted on the drive element so that there are many possible ways of mounting the spray head. Range of application: Liquid throughput: 800 ‑ 1200 l/h Operating pressure: 50 ‑ 100 bar Variants: Laid length up to 2000 mm Automatic insertion and retraction device HKF 50 PO – Cleaning from top – throughput up to 3000 l/h HKF 50 PU – Cleaning from below – throughput up to 3000 l/h System solutions: Complete cleaning systems with high-pressure pump/s, hot water generation, automatic cleaning process on request.

Reviews

There are no reviews yet.